Cost-saving packaging

Example 1. Stackable or Un-stackable, Cost Matters.

Our partner in Ecuador, Schryver company, asked us to ship 2 wooden cases of machinery from Shanghai to Guayaquil in one 40’flat-rack. The term of shipment is FOB and the consignee will pay the ocean freight.

We checked the dimension and found we could save freight cost if these wooden cases could be stackable. But the shipper told us the consignee has agreed to use 1×40’FR.

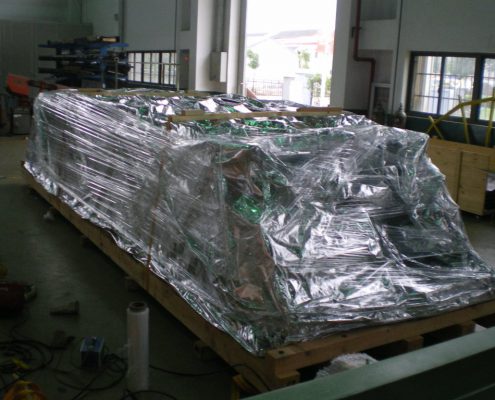

So we informed our partner of our proposal to reinforce the packing (see next slide for pictures) and to make the wooden cases stable. Our partner trusted us and our packaging people did a great job. This shipment was finally shipped in a 20’FR and we saved about USD6000.

Example 2. Improving packaging lowers the cost

We have a German customer in Shanghai, a manufacturer of production machinery for customers like Michelin, Continental, etc. They previously seek two separated companies to do the packaging and the logistics respectively.

The packaging company only cared about the safety of goods and did not pay much attention to the dimensions of the packages. So each time when a line for tire production machinery was exported, the logistics company would use 12×40’HQ to load all the machines.

When we were invited by this German customer to do packaging and logistics, we re-designed the packaging solutions to make all the packages to fit better into the containers and finally only 10×40’HQ is used. We not only saved on ocean freight, but also the total logistics charges from the shipper to the consignee which includes trucking charges, port charges, THC, etc.